South Korean semiconductor foundry company SK Keyfoundry has agreed to supply power semiconductors for fitment in Tesla vehicles from the second half of 2024, according to local reports.

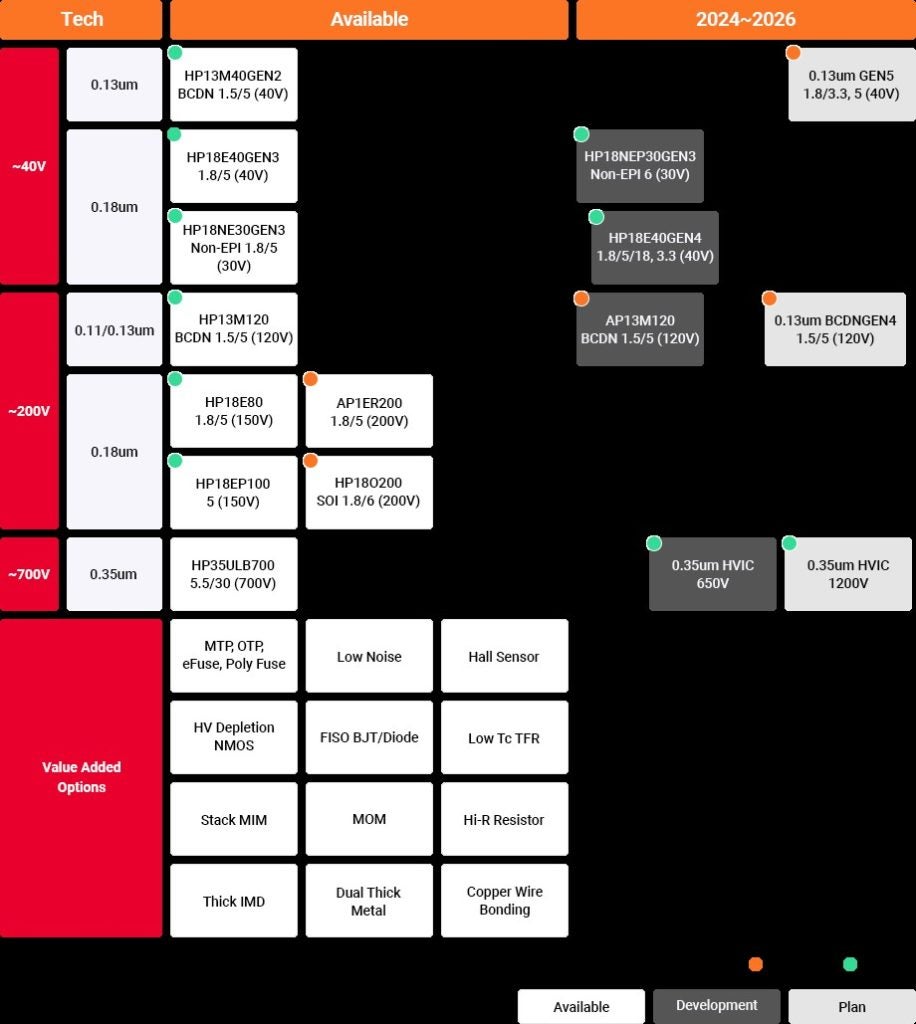

The company, known as Key Foundry before it was acquired by local chipmaker SK Hynix in 2022, last month unveiled a new improved 0.13㎛ BCD process for the production of high-performance automotive power semiconductors. The company is specifically targeting fabless producers of automotive power chips, with the aim of helping automakers compete with China’s increasing dominance of the global battery electric vehicle (BEV) segment.

The Chinese government has been nurturing the development of local foundry companies such Hua Hong Semiconductor and Semiconductor Manufacturing International Corporation (SMIC) with substantial subsidies. According to reports these companies have significantly lowered their prices for local automakers, helping them gain their competitive edge.

SK Keyfoundry is understood to be ready to begin producing its Power Management Integrated Circuits (PMIC) to be used in Tesla’s BEVs from July at its 8-inch wafer fab in Cheongju – some 100km south of the South Korean capital Seoul. The facility, which has a production capacity of 100,000 8-inch wafers per month, specialises in multi-product small-quantity production.

The deal with the world’s largest BEV producer is seen as a major breakthrough for the company, given Tesla significant influence in the global BEV industry in terms of setting technology standards. The automaker is known for its stringent requirements for semiconductors, for which reliability and performance is critical.

SK Keyfoundry has also been working to supply its new chips to leading global automotive component manufacturers such as Bosch and Continental.